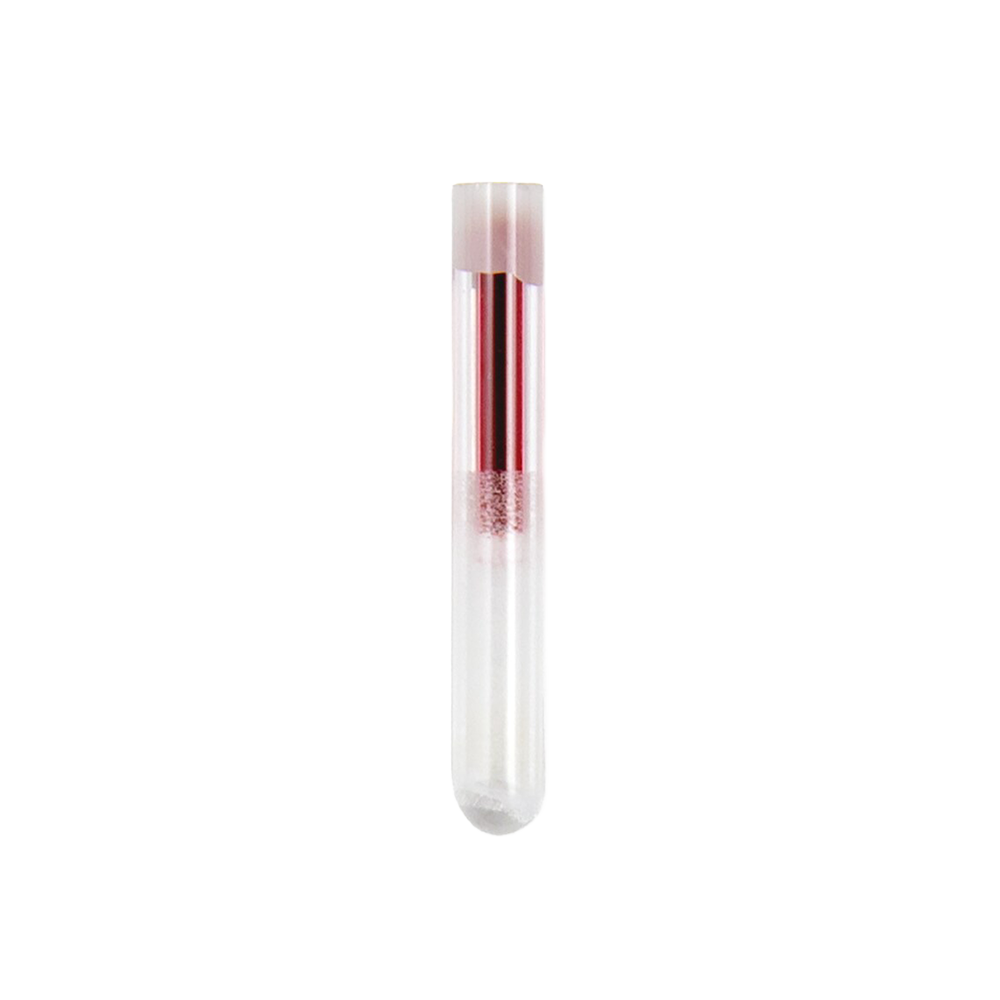

ShockWatch Tube

The ShockWatch Tube is a proven, highly visible impact indicator that uses a spring-loaded mechanism to detect and record shock events. Designed for long-term use on equipment or sensitive assets, this rugged monitoring solution delivers real-time insight into potentially damaging mishandling, helping businesses protect valuable machinery and goods in transit or storage.

Unlike standard impact labels, the ShockWatch Tube is built for durability and can monitor over time, making it ideal for large equipment, heavy industrial goods, and sensitive machinery. By revealing impact occurrences with clear, tamperproof evidence, it supports quality assurance, warranty protection, and claims validation across the supply chain.

Trusted worldwide, the ShockWatch Tube provides manufacturers and logistics providers with accountability, transparency, and peace of mind. For companies in South Africa seeking reliable industrial impact monitoring, the ShockWatch Tube is a cost-effective solution to reduce losses and improve shipment handling.