ShockWatch 2

Features

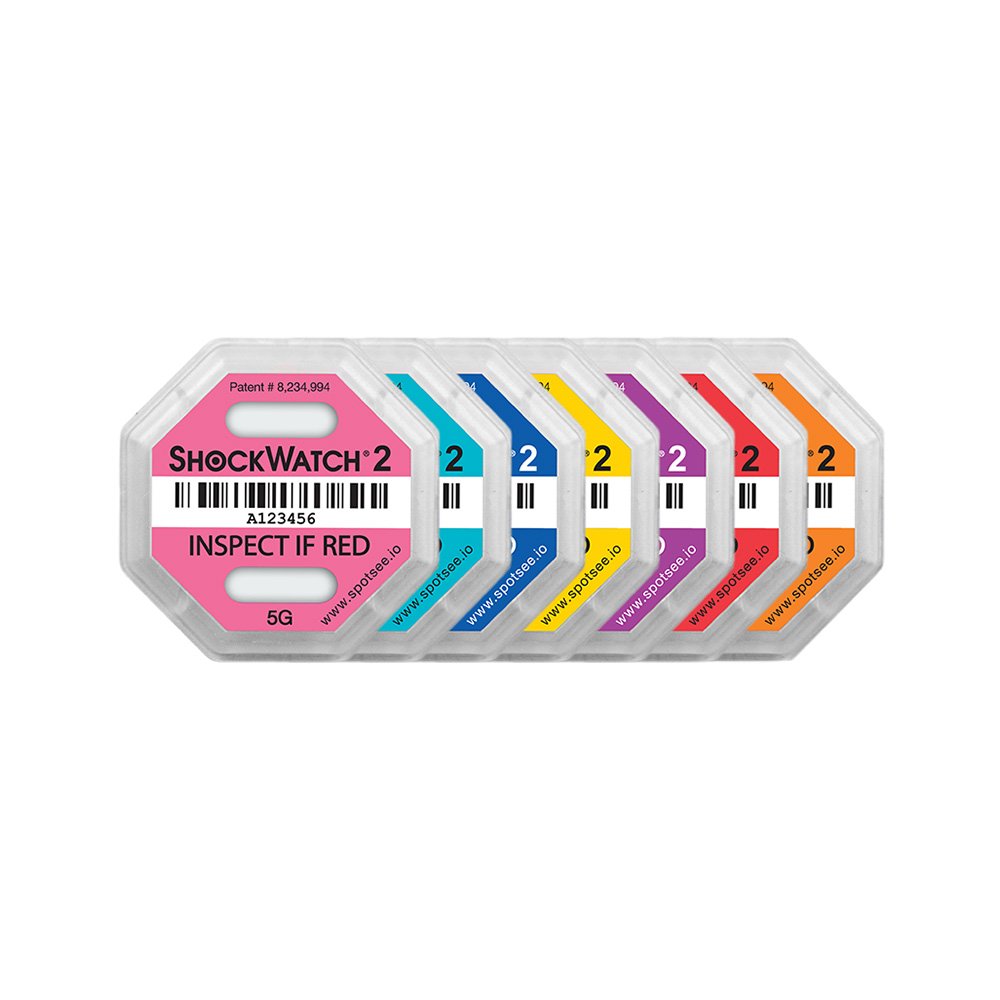

ShockWatch 2 impact indicators

Deter mishandling and reduce damage related costs by indicating when products have been exposed to a potentially damaging impact during transit generally for larger, heavier products. ShockWatch 2 is a bi directional vertical response impact indicator.

Selecting the most suitable ShockWatch 2 impact indicators:

Available in seven sensitivities, as indicated by the seven different colours – simply match the sensitivity of the ShockWatch 2 to the level of impact the product and packaging can withstand based on any non operating shock specifications that the product may have or select a ShockWatch 2 based on the mass and size of your shipment from our ShockWatch 2 Selection Guide below.

ShockWatch 2 Labels visually deter and detect mishandling:

The ShockWatch 2 impact indicators mount to the exterior of packaging of a shipment and visually alerts everyone involved in the handling of the package that additional care is required. If mishandling occurs during the shipment and handling cycle, the ShockWatch 2 serves as a permanent record of mishandling.

If a package has not been mishandled, the top or bottom window of the ShockWatch 2 will remain white. If the package has been mishandled, either top or bottom window will show red colouration. Any red in the either of the ShockWatch 2 windows alert receivers to inspect the package for potential damage.

Economical solution to reduce your damage related costs:

ShockWatch 2 impact indicators offer an economical solution to prevent damage during product transit.

Indicate when mishandling has occurred with ShockWatch 2 impact indicators:

The ShockWatch 2 impact indicators are not indicators of damage, they are an indicator of mishandling. If a shipment arrives at a destination with an activated ShockWatch 2, the receiver should immediately note any visible damage to the shipment, open the package and inspect for any damage to the goods.

Using ShockWatch 2 impact indicators to determine if any damage to the product may have occurred requires in house drop testing to ascertain the ShockWatch 2 which is most suitable. This may lead to reducing the number of inspections that may have to be performed by the end user.

Applications

- Energy and Utilities

- Furniture and Fixtures

- Auto and Truck Parts

- Metal Fabrication

- Consumer Electronics

- Telecommunications Equipment

- Network Equipment

- IT Hardware

- High Tech Equipment

- Instrument Panels

- Logistics & Transport

- Packaging/Crating

- Networking Hardware

- Medical Supplies

- Medical Devices

- Aerospace Components

- Defense Components

- Small Distribution Transformers

Specs

Operating Temperature

-25°C to 80°CSize

42.93 x 42.93 x 6.35 mm

Sensitivity

5G to 75G

Guaranteed Activation

+/-15% of nominal value

Security: Tamper Proof, Serialized (OCR Format)Responsiveness

Responds to single impact

Duration

Ranges 0.5 to 50 ms

Adhesive:

Acrylic

Shelf Life

2 years when stored at standard temperature and pressure (20°C / 68° F, 1 ATM)

Benefits

- Acts as a visual deterrent to improper handling

- Reduces mishandling through awareness

- Provides indisputable evidence of mishandling

- Promotes chain of accountability for all product handling

- Confirms effectiveness of packaging

- Helps identify trouble spots in the supply chain, from production to transportation and storage

- Helps increase the quality of product from dock to dock