INDUSTRIES

Reliable Damage Prevention Solutions for Goods in Transit

In oil and gas, downtime isn’t just costly — it’s catastrophic.

Critical equipment like pumps and compressors used in exploration and extraction are highly vulnerable to damage during transit and deployment in harsh environments. Even minor impacts can result in major operational delays and expensive repairs.

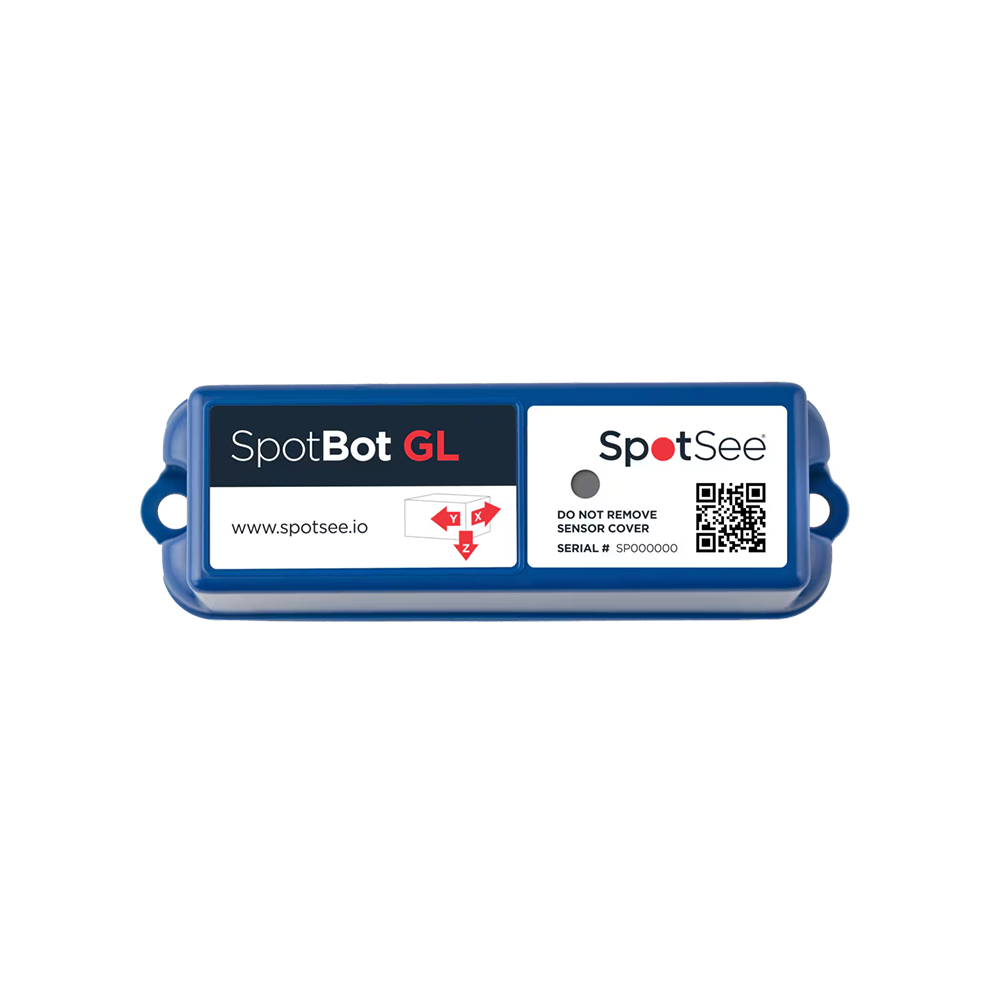

ShockWatch Africa delivers early warning systems that monitor and report damage before failure occurs. With solutions like SpotBot Cellular, ShockLog Satellite, and ShockLog 298, you gain real-time visibility into:

Impact and vibration events

Signs of wear or rough handling

Conditions that trigger maintenance alerts

These devices allow operators to assess equipment before it goes into service, helping prevent unnecessary downtime and ensuring uptime in remote, high-risk environments.

For ongoing vibration monitoring, OpsWatch streams continuous data via Wi-Fi, notifying your team when equipment performance falls outside safe parameters — days before failure strikes.

In a sector where every second matters, predictive insight is your competitive edge.

In warehousing and e-commerce, damaged goods mean lost profits — and lost customers.

When products arrive damaged, the blame often falls on your brand — even if the issue occurred during shipping. Returns increase, reviews suffer, and customer loyalty drops.

ShockWatch indicators give you the tools to fight back.

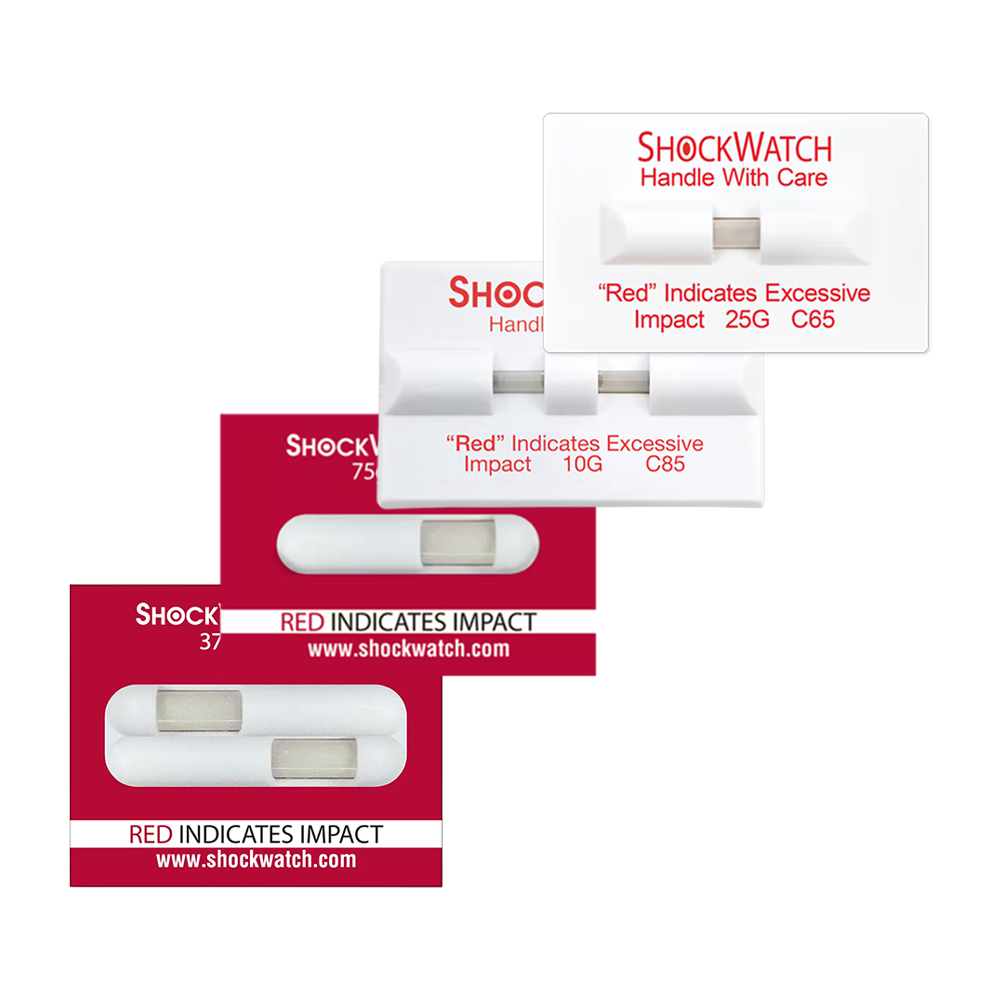

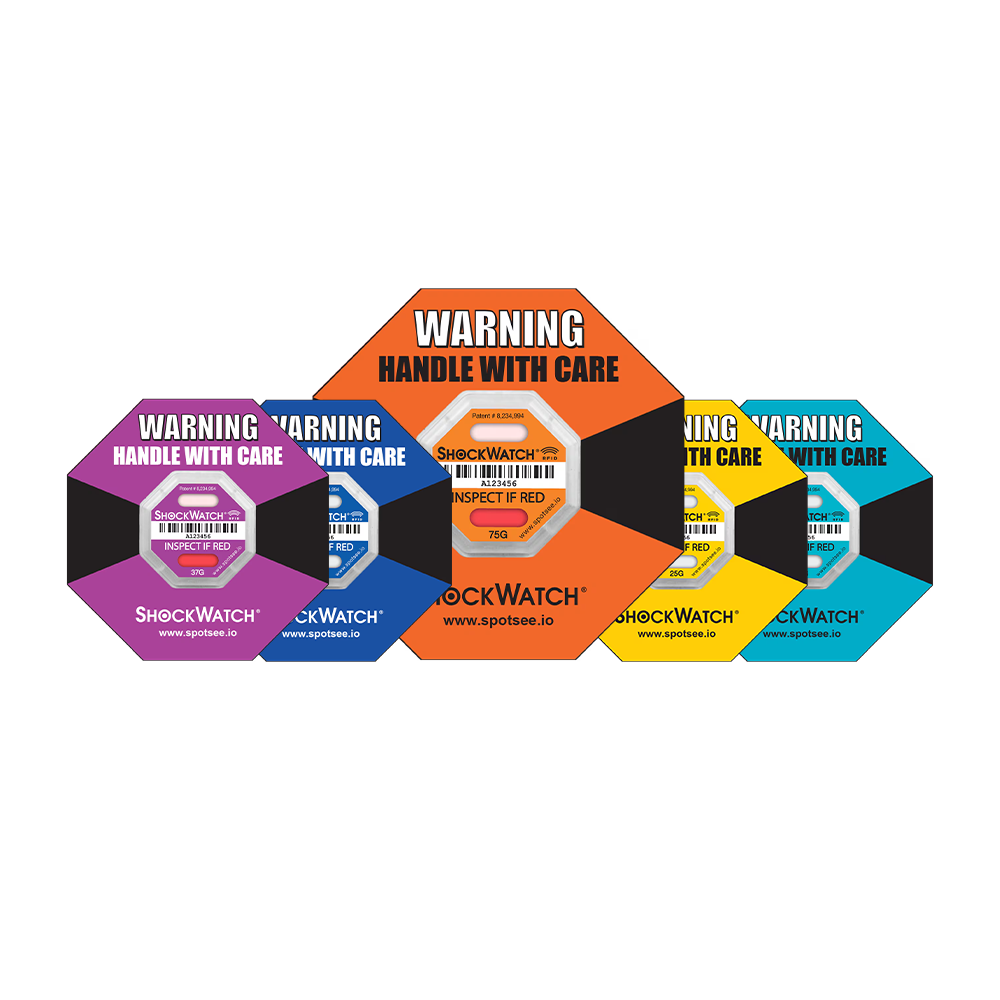

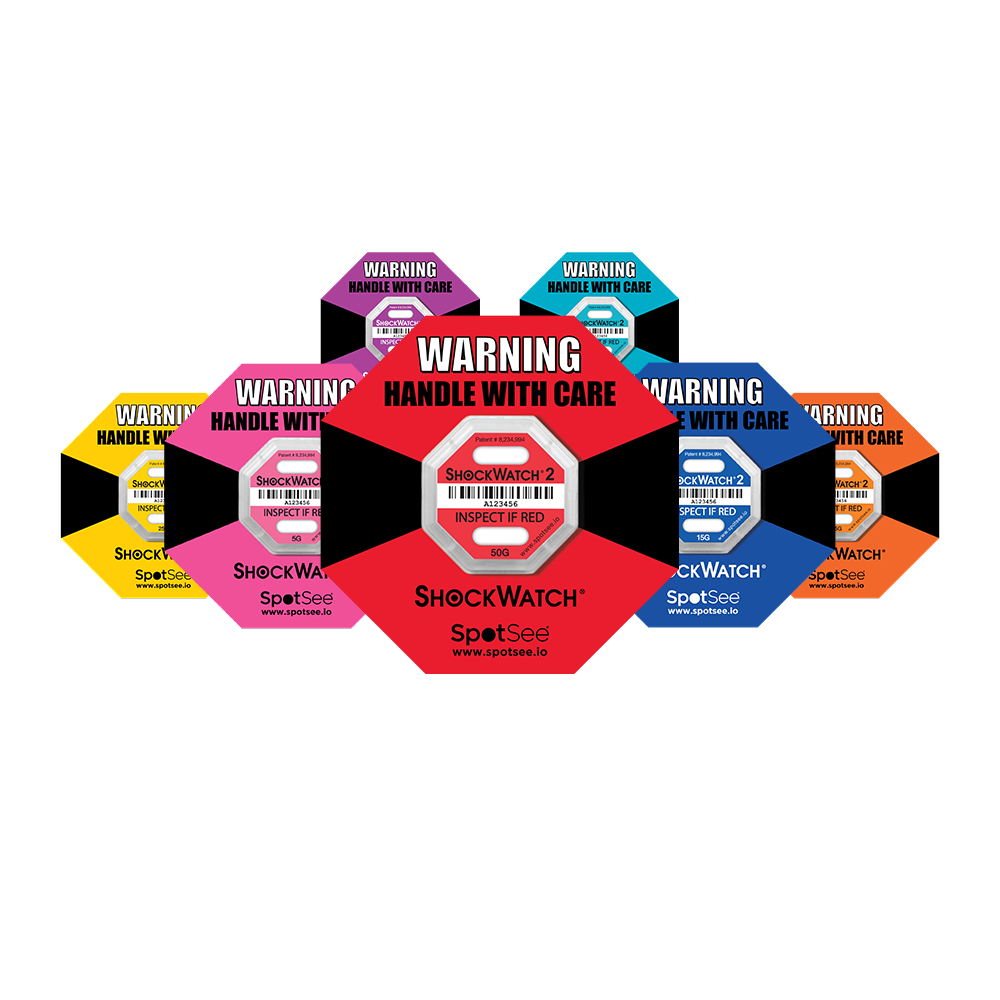

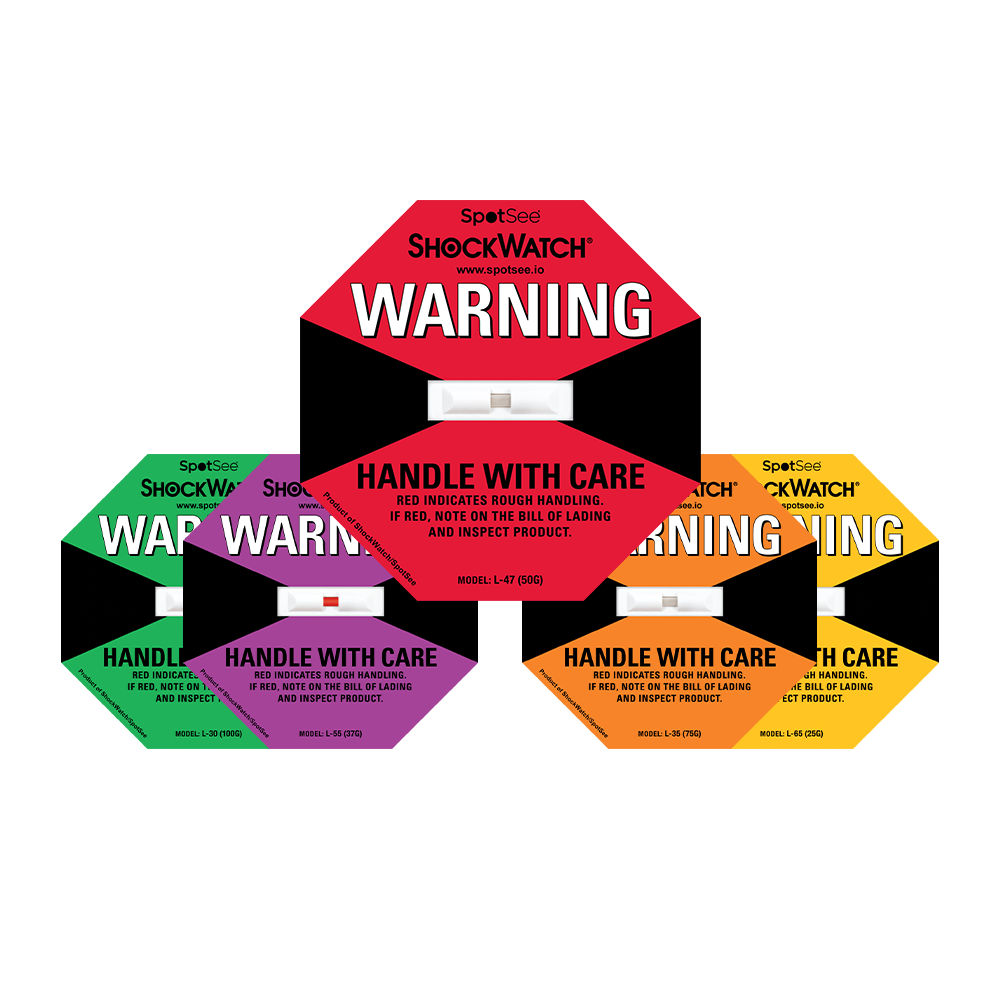

ShockWatch 2 and ShockDot activate when a package experiences impact above a pre-set threshold.

TiltWatch indicators detect when packages that must remain upright are tilted during storage or handling.

These highly visible devices act as a powerful deterrent against mishandling and provide indisputable proof of damage — helping you hold carriers accountable.

With ShockWatch, every package comes with a built-in warning label: "Handle with care — or else it shows."

In power generation, equipment failure isn’t an inconvenience — it’s a crisis.

Transformers, turbines, and critical components are massive, expensive, and often irreplaceable in the short term. A single unit can weigh over 400 tons and cost between $3–11 million. If damaged in transit, sourcing a replacement could take months, leading to devastating project delays and financial loss.

That’s where ShockWatch monitoring systems come in.

Solutions like ShockLog 298, ShockLog Cellular, ShockLog Satellite, and SpotBot Cellular (with real-time GPS and impact tracking) give you complete visibility into:

Impact and vibration events during transit

Handling anomalies that could compromise structural integrity

Real-time alerts to act before damage becomes disaster

When your cargo is critical and the margins for error are razor-thin, you need data, not hope.

In mining, the cost of downtime is measured in tonnes of lost output and millions in repairs.

Heavy equipment used in excavation and material handling operates under extreme stress — and when it fails, everything stops. The ShockWatch OpsWatch system provides real-time monitoring of vibrations and impact events via Wi-Fi or Ethernet, helping you detect early signs of mechanical fatigue before breakdowns occur.

On busy and noisy sites, safety is equally critical. The ShockWatch Proximity Alert System by KIGIS, powered by Ultra-Wideband (UWB) technology, monitors the distance between mobile equipment and pedestrians — dramatically reducing the risk of collisions in blind spots or dynamic work zones.

Protect your people. Extend your equipment life. Keep production moving.

Chemical products are only as stable as the conditions they're kept in.

When chemicals are exposed to temperatures outside their designated range, they risk becoming unstable, ineffective, or hazardous. That’s why temperature monitoring during storage and transport is essential.

ShockWatch offers a layered approach to protection:

WarmMark: single-use visual indicator of temperature breaches

LOG-IC: digital temperature recorders with downloadable data logs

SpotBot BLE: monitors and logs temperature, humidity, impact, tilt, and roll

SpotBot Cellular: real-time alerts when a shipment moves out of safe parameters

These solutions give you full visibility and compliance assurance — from loading dock to delivery.

When safety and regulatory compliance are on the line, ShockWatch gives you the control you need.

In construction, one overlooked vibration or mishandled tool can bring an entire project to a standstill.

Busy, noisy job sites demand more than just awareness — they demand visibility and control. The ShockWatch Proximity Alert System by KIGIS, powered by Ultra-Wideband (UWB) technology, helps reduce the risk of collisions between pedestrians and heavy machinery by accurately measuring distances and triggering alerts in real-time.

To prevent costly equipment failures, the OpsWatch WiFi vibration recorder provides live monitoring of critical tools and machines, helping you detect abnormal conditions before they lead to breakdowns, delays, or safety incidents.

For sensitive or calibrated gear like laser levels, ShockWatch Clip indicators offer tamperproof, visual confirmation of mishandling. These devices turn bright red if dropped or mishandled, even when tools are packed inside protective cases.

On today’s fast-paced construction sites, proactive monitoring is the difference between smooth delivery and expensive rework.

In life sciences, cold chain failure isn’t just costly — it’s critical.

Vaccines, blood, biologics, and temperature-sensitive medicines must remain within strict temperature ranges from production to patient delivery. A single breach can compromise efficacy, patient safety, and compliance.

ShockWatch solutions ensure you maintain full visibility and traceability at every stage of the journey:

WarmMark and Timestrip PLUS: single-use indicators showing if and when a shipment exceeded safe temperature thresholds

Blood Temp Indicator: designed specifically for monitoring the core temperature of blood bags

LOG-IC: digital temperature data loggers with downloadable history

Timestrip Time Indicators: help nurses track dosage intervals and cannula changes with visual clarity

Whether it’s for COVID-19 vaccines or high-value biotech shipments, our temperature indicators provide visual proof and real-time alerts when your cold chain is compromised.

In an industry where precision equals protection, ShockWatch keeps your supply chain within the safe zone.

Medical equipment is highly sensitive—handling errors can cost lives.

Whether it’s photomultiplier tubes used in hygiene monitors or field hospital devices transported under emergency conditions, vibration, shock, and tilt can cause critical damage. Even slight mishandling during shipping or air evacuations may render equipment unusable.

ShockWatch provides the monitoring solutions needed to protect this sensitive cargo:

SpotBot Cellular: Ideal for medical equipment under 27,000kg, offering real-time alerts for impact, tilt, temperature, and roll.

ShockLog 298: Suited for heavier medical devices, providing detailed incident data after transit.

ShockLog Cellular: The premium choice when real-time visibility is essential for high-value shipments.

Our devices ensure medical assets arrive ready to save lives—no surprises, no failures.

When precision equipment is in transit, ShockWatch gives you certainty in every shipment.

Temperature abuse = spoiled goods and wasted revenue.

Fresh produce, dairy, and meat are highly sensitive to temperature fluctuations. Without proper cold chain monitoring, even short exposures to unsafe conditions can cause irreversible spoilage, shrink your profits, and harm brand reputation.

ShockWatch helps you stay in control:

WarmMark: Single-use temperature indicator that gives irrefutable proof of temperature breaches.

LOG-IC Temperature Recorders: Track and log detailed temperature data for audit trails and compliance.

SpotBot Cellular: Sends instant real-time alerts when temperature thresholds are breached—along with trip history and GPS tracking, all accessible on the SpotSee Cloud.

In busy cold storage warehouses, worker safety and cargo integrity go hand in hand. Our pedestrian alert and collision avoidance systems help reduce accidents involving forklifts and protect your stock from impact-related damage.

Protect your perishables. Prevent spoilage. Preserve your profits.

In freight, timing matters. But today, visibility matters more.

Modern logistics isn’t just about getting shipments from point A to B—it’s about ensuring complete transparency across every mile of the journey. From air cargo to ocean freight, supply chain stakeholders demand real-time data on impact, temperature, tilt, and location to make informed decisions fast.

With SpotBot Cellular, you get:

Real-time alerts for impact, tilt, and temperature breaches.

GPS tracking with live visualisation via the SpotSee Cloud.

Full shipment history at your fingertips.

Extreme cargo hold temperatures, delays, or improper storage can compromise your goods. ColdMark temperature indicators offer cost-effective, single-use verification of low-temperature exposure—essential for ensuring product integrity during transit.

Shipping docks also pose safety risks. Blind spots, doorways, and fast-moving forklifts create an accident-prone environment. Our proximity alert systems help prevent collisions between people and machines, protecting both personnel and cargo.

Supply chain visibility. Risk reduction. Operational control—simplified.

When precision tech is mishandled, projects—and profits—suffer.

From robotics and manufacturing tools to premium electronics and commercial kitchen gear, high-value equipment is vulnerable to hidden damage during transit. A single mishap can halt an entire operation—whether it's a delayed factory launch or a restaurant grand opening.

That’s why smart businesses trust ShockWatch impact and tilt indicators:

Identify mishandling the moment it happens.

Drive accountability throughout your supply chain.

Reduce shipping damage by up to 70% with proven monitoring tools.

When handlers know a shipment is being monitored, they act more carefully. That’s simple, effective damage prevention—built into every box.

Avoid delays. Cut costs. Protect your technology investment.

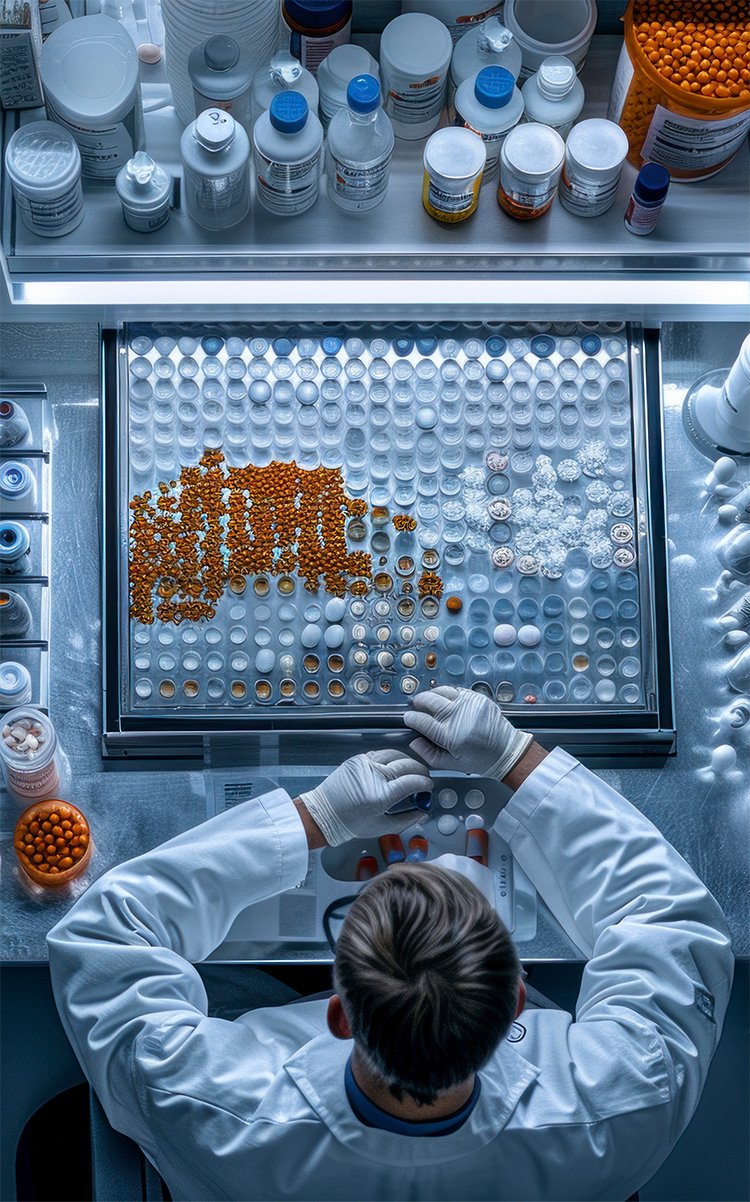

When medicine is mishandled, patient safety — and trust — are at risk.

From vaccines and insulin to specialty drugs and biologics, pharmaceuticals are highly sensitive to temperature, light, and shock. A single excursion during transport can compromise the product’s efficacy or make it unsafe. With regulations tightening and supply chains growing more complex, visibility and control are non-negotiable.

That’s why the pharmaceutical industry relies on ShockWatch temperature and impact indicators:

Detect and document temperature breaches in real time.

Maintain cold chain integrity from manufacturer to patient.

Ensure compliance with global pharmaceutical transport regulations.

When logistics teams use damage and temperature monitoring, they catch problems before they become costly recalls. That’s smarter, safer delivery — in every vial, blister pack, and box.

Protect your products. Maintain compliance. Safeguard patient health.

When IT infrastructure is compromised in transit, uptime — and trust — go offline.

From high-performance servers and storage arrays to networking gear, data center equipment is precision-built and sensitive to shock, tilt, and vibration. Even a small mishandling during transport can lead to latent failures, costly returns, or critical system downtime.

That’s why data center operators rely on ShockWatch impact and tilt monitoring solutions:

Detect mishandling during shipping, installation, or relocation.

Hold third-party logistics providers accountable.

Prevent costly downtime and safeguard hardware integrity.

When data center components are protected by monitoring tools, teams gain visibility and confidence. That’s efficient infrastructure protection — from warehouse to rack.

Keep systems online. Reduce failures. Protect your mission-critical assets.

When blood temperature isn't controlled, lives—and reputations—are at risk.

Blood products are highly perishable and must be stored and transported within strict temperature ranges. A single exposure to excessive heat or cold can render a blood bag unusable—wasting resources and putting patients at risk.

That’s why hospitals and logistics teams trust ShockWatch Blood Temp indicators:

Visibly show if core blood temperature exceeds safe limits.

Ensure compliance with blood handling protocols.

Eliminate manual recordkeeping with easy-to-read indicators.

With single-use, irreversible indicators on every unit, staff can verify safe transport at a glance—no guesswork, no compromises.

Protect patient safety. Maintain compliance. Preserve every drop.

When parts arrive damaged, production stops—and deadlines are missed.

From precision engine components to fragile electronics and body panels, automotive parts face vibration, impact, and mishandling risks throughout the supply chain. Even minor damage can delay assembly lines or result in costly warranty claims.

That’s why leading manufacturers rely on ShockWatch impact and tilt indicators:

Detect mishandling at every stage of transport.

Ensure accountability from supplier to assembly line.

Reduce costly delays and product rework with visible damage alerts.

These simple, tamper-proof tools are trusted to maintain part integrity—so your builds stay on time, and your reputation stays intact.

Deliver quality. Prevent damage. Keep production moving.