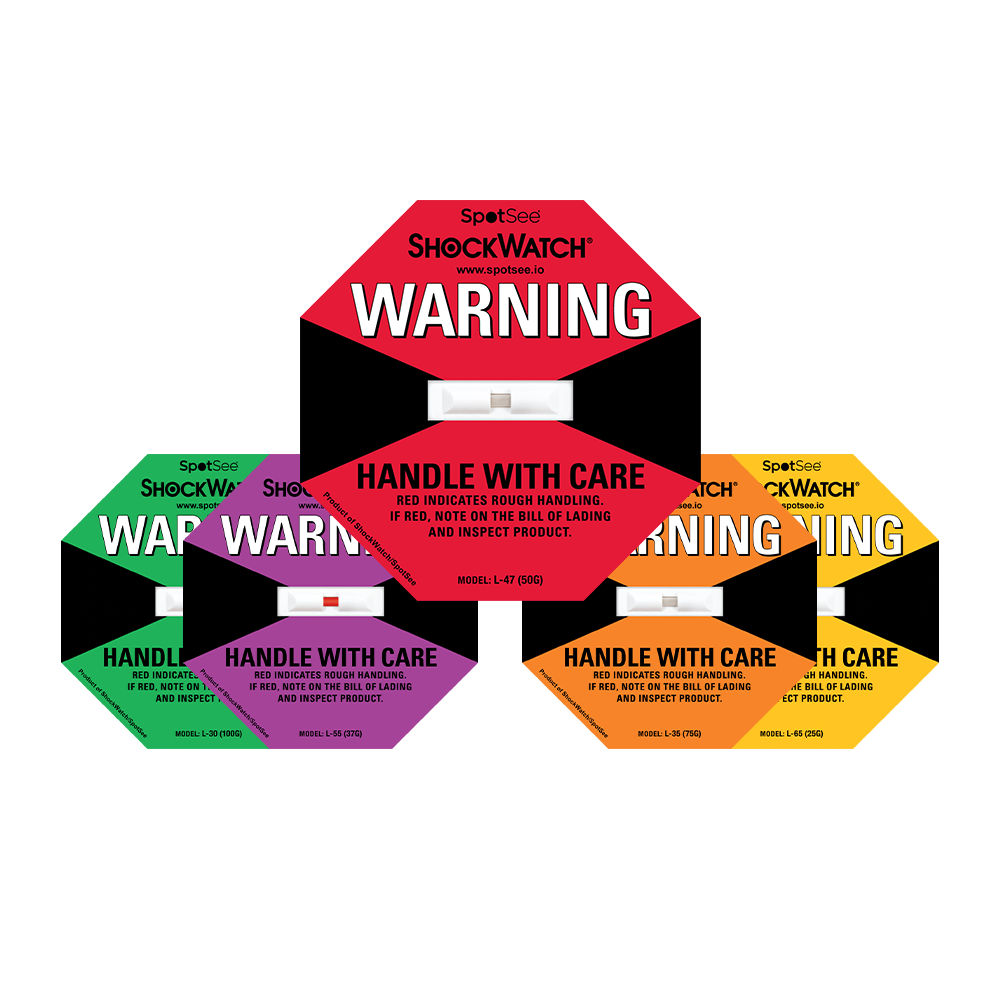

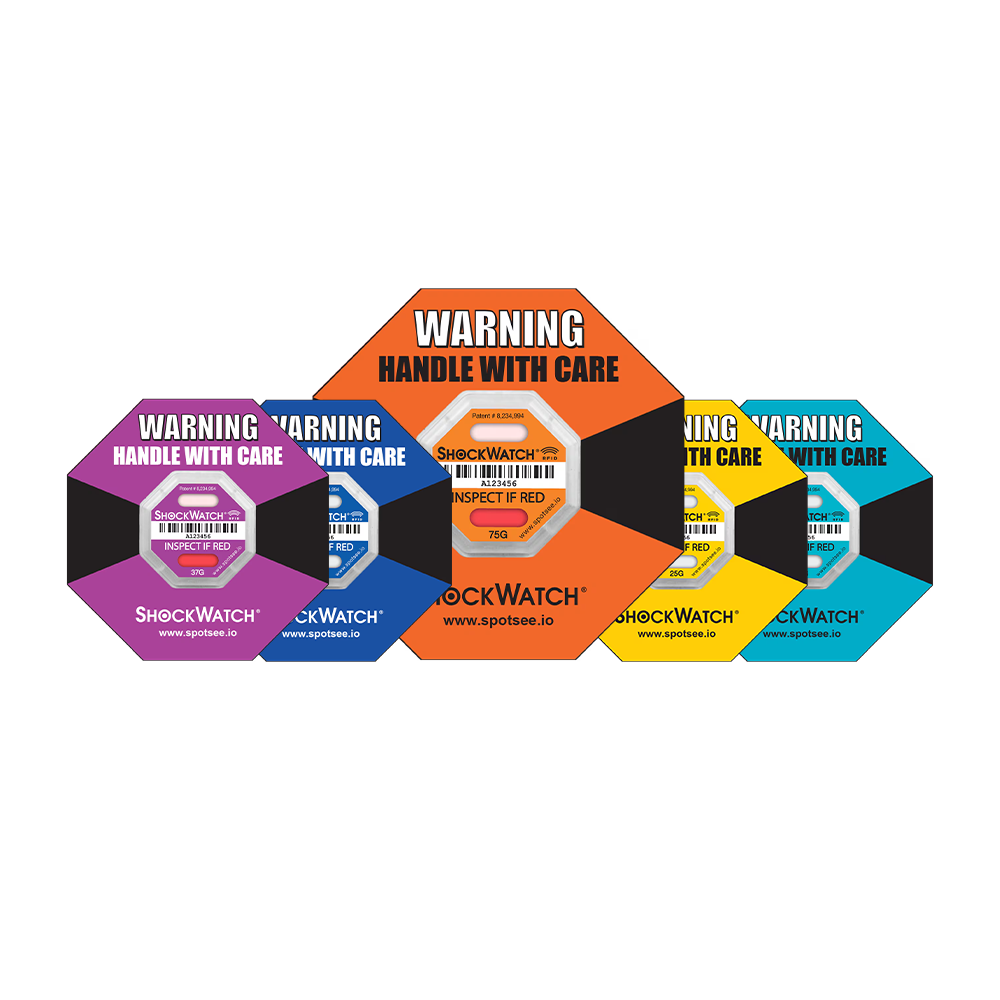

ShockWatch Labels

ShockWatch Labels are tamperproof, single-use impact indicators that provide a clear visual alert when a shipment has been mishandled. When an impact exceeds the set threshold, the label permanently changes color, alerting receivers to inspect the package before acceptance. This simple but powerful solution ensures accountability at every point in the supply chain.

Designed for high-value or sensitive shipments, ShockWatch Labels help reduce product losses by deterring mishandling and improving visibility during transport and storage. They are easy to apply, cost-effective, and impossible to reset, making them a trusted solution for industries that require reliable handling verification.

By promoting better handling practices, ShockWatch Labels support quality control efforts, warranty protection, and claims validation. For businesses in South Africa, these impact labels provide an effective way to safeguard shipments, improve accountability, and maintain customer satisfaction.