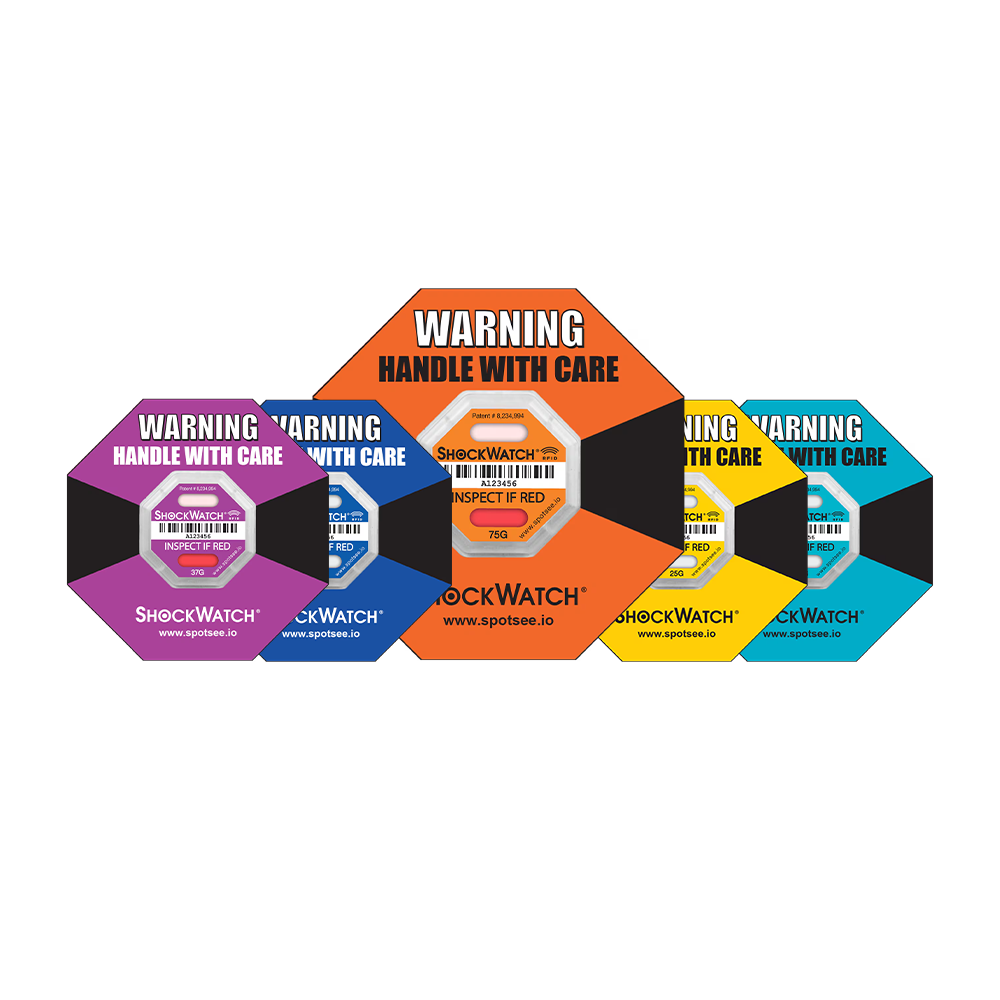

ShockWatch RFID

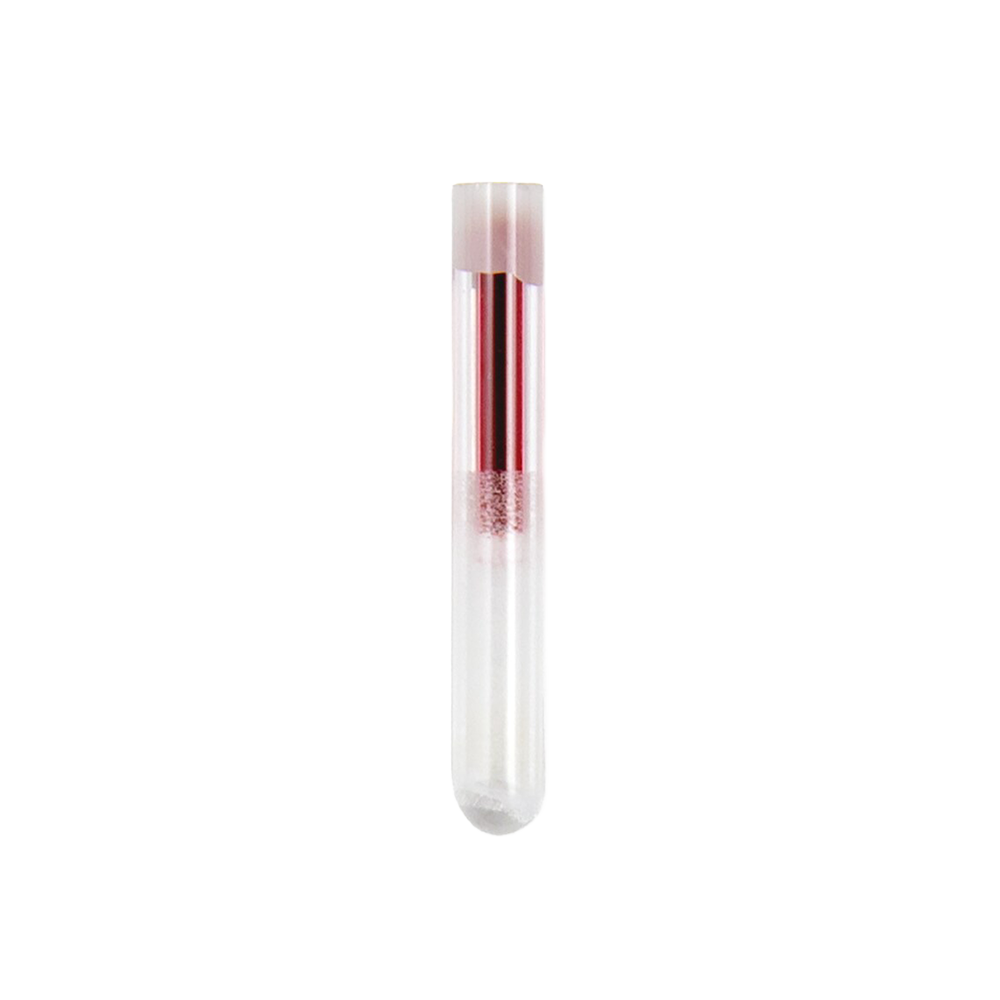

The ShockWatch RFID combines proven ShockWatch impact indicator technology with RFID scanning systems to deliver a tamperproof, automated solution for impact detection and inventory management. This smart passive RFID label turns red when an impact occurs and can be wirelessly scanned using standard UHF RFID readers, eliminating the need for manual inspection of each shipment.

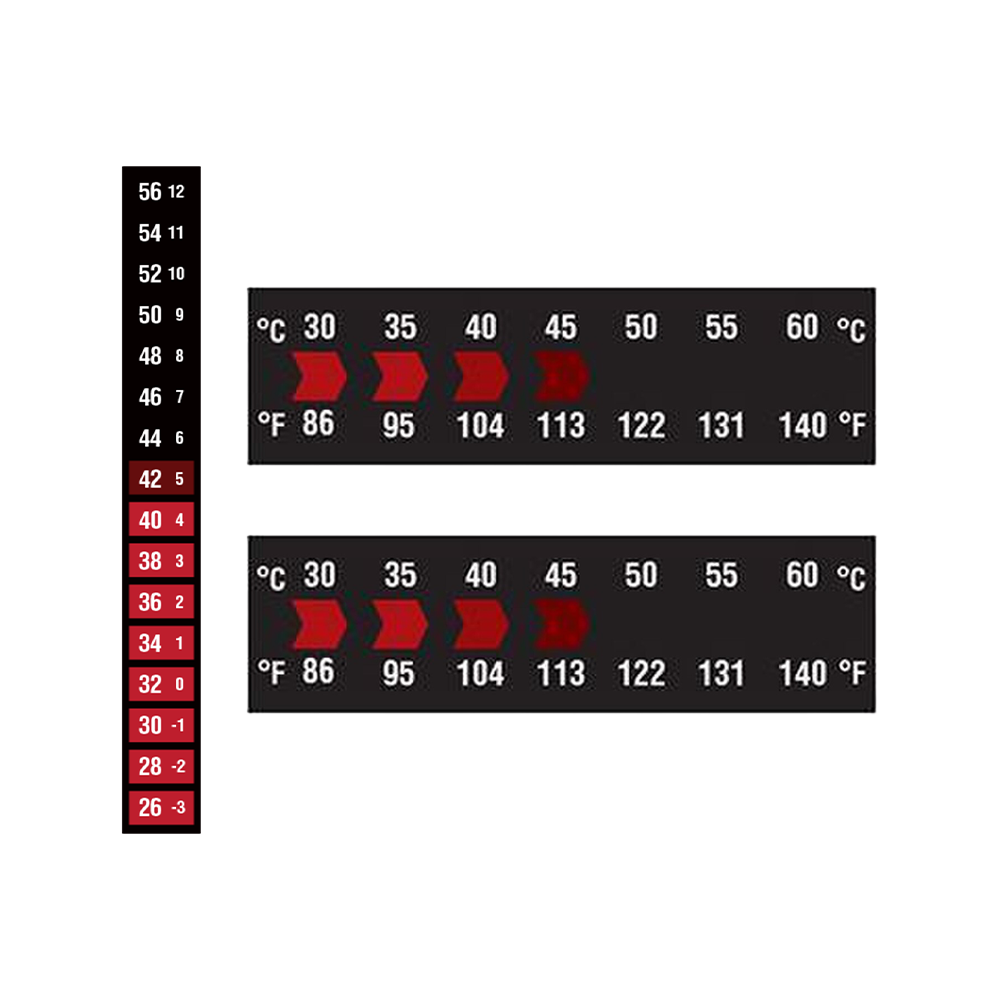

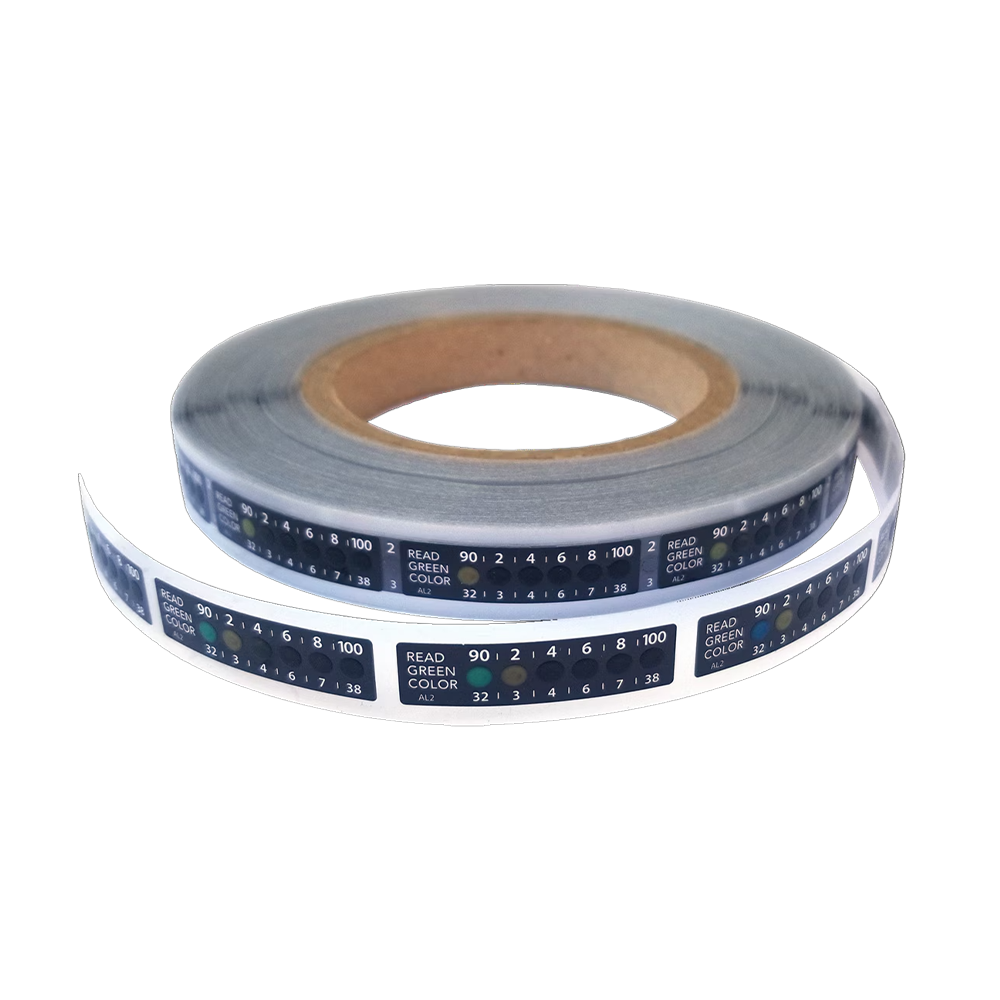

Designed for logistics, manufacturing, and cold chain operations, the ShockWatch RFID enables supply chain teams to instantly identify damaged goods, improve accountability, and streamline receiving processes. By embedding impact detection into existing RFID systems, businesses gain faster inspection times, improved traceability, and reduced risk of shipping damaged products.

Ideal for South African industries such as pharmaceuticals, electronics, and industrial equipment, ShockWatch RFID helps companies extend the benefits of RFID programs with integrated damage monitoring. This innovation ensures greater visibility, compliance, and cost savings across the supply chain.