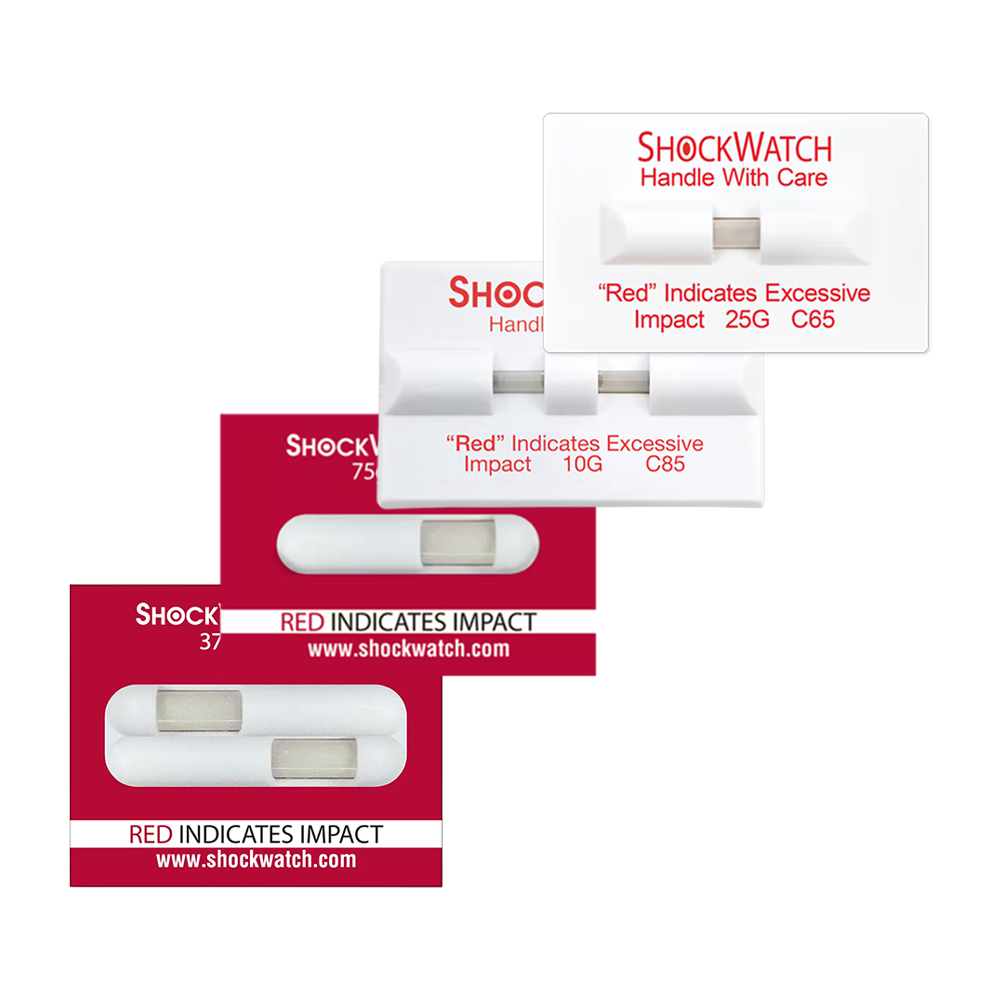

ShockWatch Clip & Flex

The ShockWatch Clip & Flex are compact, highly visible impact indicators designed to provide clear evidence of mishandling once a product is removed from its protective packaging. Unlike standard impact monitors, these indicators adhere directly to products and deliver 360° detection coverage, making them an ideal choice for goods prone to damage, misalignment, or calibration drift during handling, transit, or installation.

Available in multiple variants including Single, Double, Mini, Double Mini, and Multi-G, the ShockWatch Clip & Flex offer manufacturers and logistics teams flexibility in monitoring solutions. By providing tamperproof visual evidence of potential mishandling, they help reduce warranty claims, enforce accountability, and improve product integrity across the supply chain.

Trusted worldwide, the ShockWatch Clip & Flex are particularly effective for shipping sensitive electronics, medical devices, and precision equipment in South Africa. They support quality assurance and ensure critical goods arrive safely at their destination.