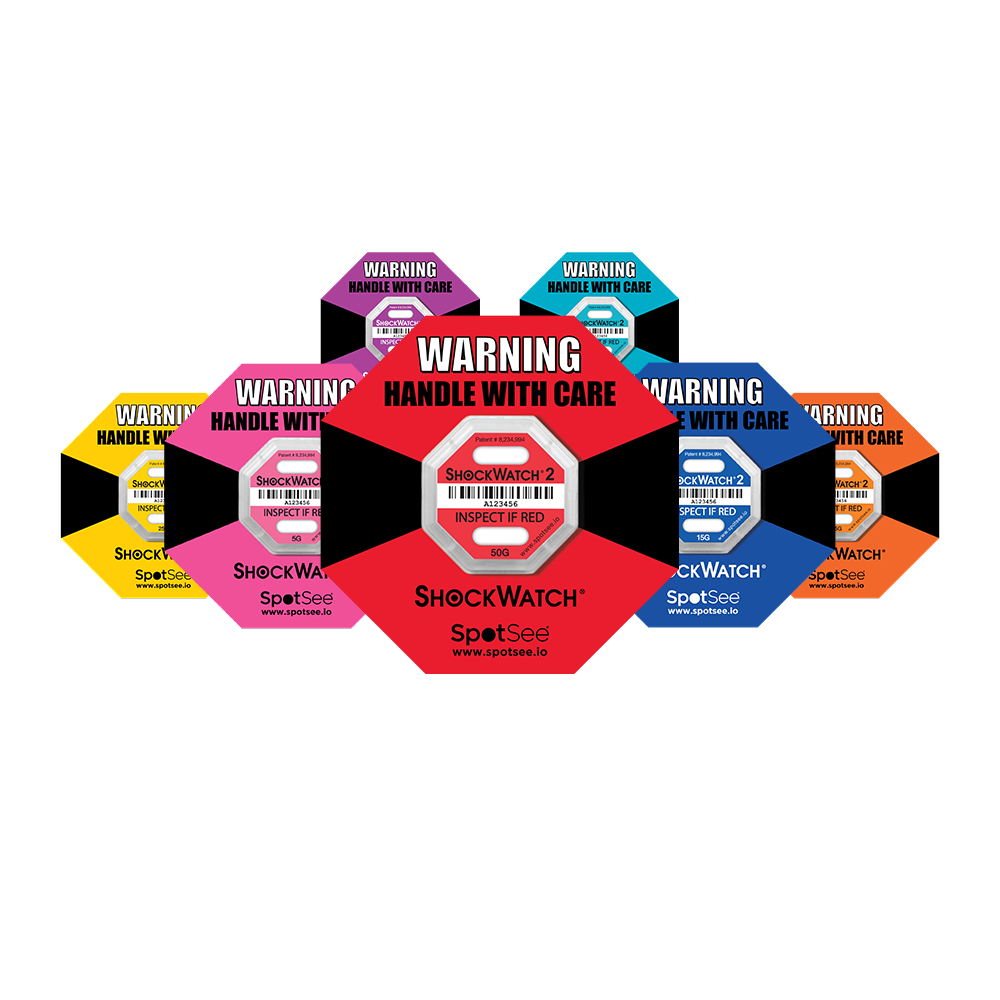

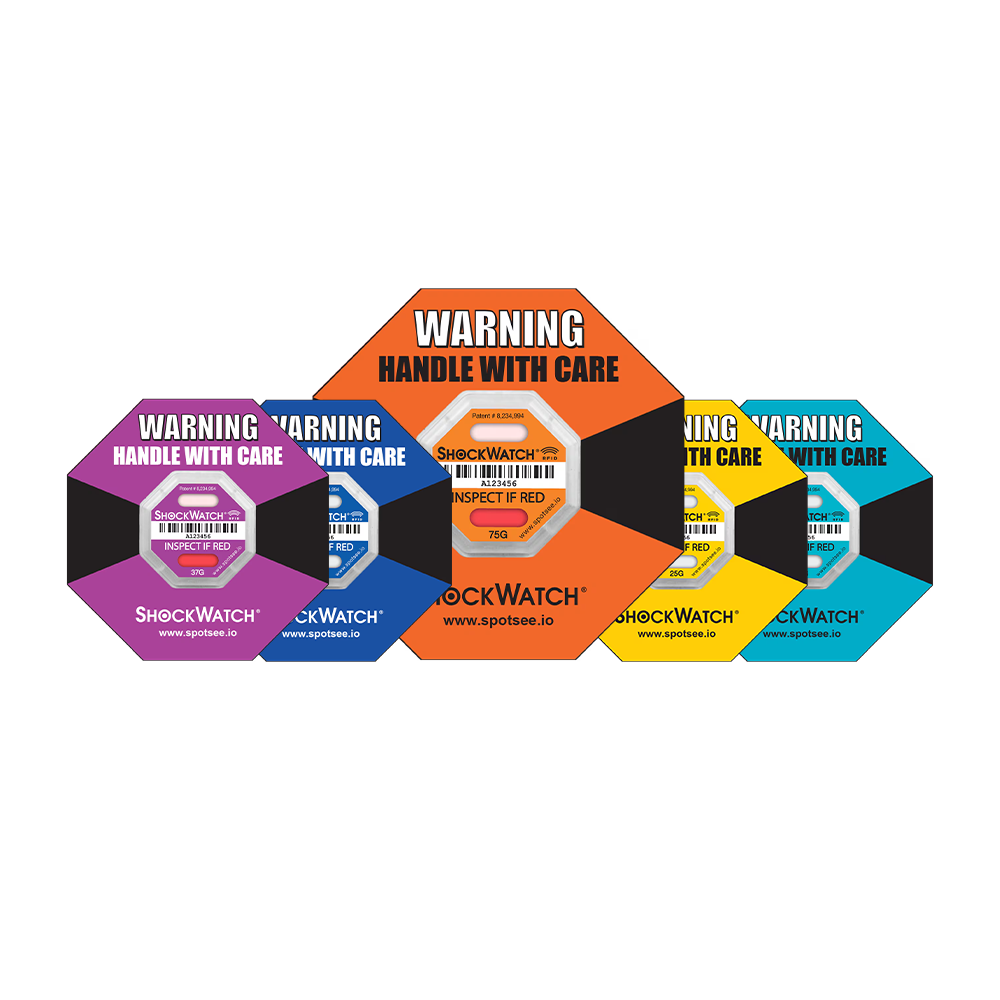

ShockWatch 2

The ShockWatch 2 is a tamperproof, single-use impact indicator that provides a clear visual alert when packages experience potentially damaging impact during transit or storage. This innovative solution uses a dual-component system with a self-activating sensor and an adhesive-backed companion label, ensuring visibility and accountability at all handling points.

Designed to reduce shipping damage by up to 60%, ShockWatch 2 helps companies cut costs, improve customer satisfaction, and minimize product losses. By providing irrefutable evidence of mishandling, it supports warranty protection and damage claim processes by identifying when and where a problem may have occurred.

Easy to apply and impossible to reset, the ShockWatch 2 is trusted worldwide across industries such as electronics, medical devices, and industrial goods. For businesses in South Africa, it offers a reliable, cost-effective way to enforce accountability and ensure sensitive shipments arrive safely.