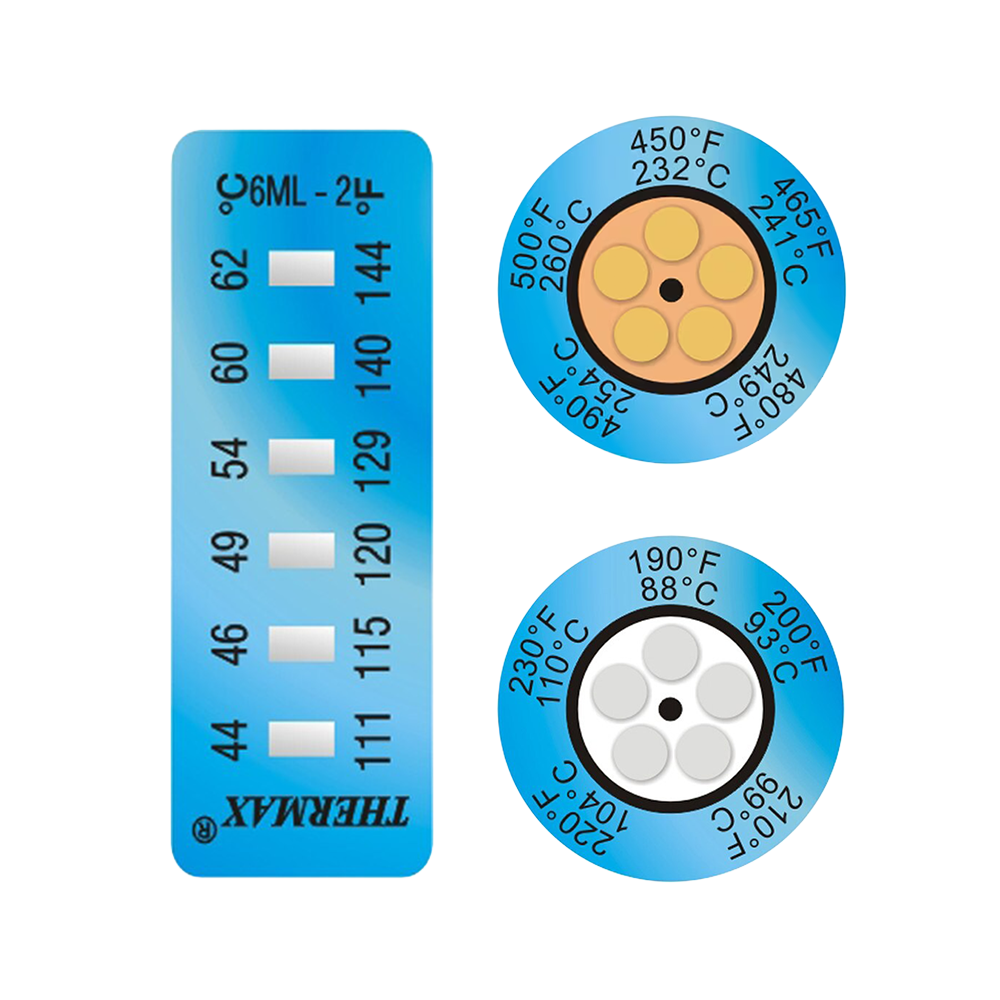

Thermax

Thermax Irreversible Temperature Indicators provide a fast, reliable, and cost-effective way to monitor heat exposure across a wide range of industrial applications. These self-adhesive labels change color permanently from clear to black when a specific temperature threshold is exceeded, creating an accurate and irreversible record of thermal events.

Designed for surface-level monitoring, Thermax indicators are widely used for process validation, equipment monitoring, and preventative maintenance. They are especially valuable in industries where heat exposure must be carefully controlled, including drying, bonding, curing, and transport operations.

Compact and easy to apply, Thermax indicators offer businesses a simple yet powerful solution for verifying product integrity and compliance with heat-sensitive processes. For manufacturers and logistics providers in South Africa, Thermax labels ensure reliable temperature history tracking, reduce risk of undetected damage, and support strict quality assurance protocols.